No products in the cart.

Acrylic is a polymer with high resistance to bending, impact, temperature changes, weathering and sunlight. It can be easily shaped, rolled, polished and machined.

Thermoplastic polymers are characterized in that they are meltable at one temperature and formable for some time.

The melting point of thermoplastic polymers is much lower than that of thermosetting polymers. Once fused, the thermoplastics can be molded. This allows obtaining products with a complex shape and a wide variety of colors.

Once the thermoplastic polymers have been molded, subsequent modification of the shape of the product is not possible.

It is part of the family of polyacrylates, with a great capacity to adapt to changes in temperature and a high degree of transparency. It is a plastic widely used in the manufacture of decorative objects, models, school supplies, toys, etc.

Table of Contents

ToggleIt has a high resistance to impacts, which makes it ideal for applications where a resistant material is required.

It is easy to manufacture and can be molded into a variety of shapes. The extruded acrylic is a popular material in the manufacture of parts because it is resistant, versatile and easy to use.

Cast acrylic is a type of plastic used in the manufacture of a wide variety of products. It is characterized by its strength, softness and transparency.

It is used in the manufacture of a wide variety of products, such as:

The strength of cast acrylic is ideal for the manufacture of products that will be subjected to intensive use or extreme conditions, such as plastic boxes or packaging.

The transparency of cast acrylic methacrylate makes it ideal for the manufacture of products that need to be clearly seen, such as transparent films or plastic windows.

Extrusion Acrylic Methacrylate is processed through an extrusion process, which means that it is molded from a solid mass through a die to produce a part with a predetermined shape and size.

Cast acrylic, on the other hand, is processed by the casting process, which involves molding a liquid in a mold to produce a part with a predetermined shape and size.

Extrusion acrylic methacrylate tends to be harder and less flexible than cast acrylic methacrylate. This is because methacrylate melts at a much lower temperature than extrusion, making it easier to mold.

Extrusion acrylic tends to be more expensive than cast acrylic acrylic due to its more complicated manufacturing process.

Extrusion acrylic is more resistant to corrosion, impact and higher temperatures than cast acrylic. This is because extrusion acrylic is processed at higher temperatures and is therefore more resistant to external elements.

It is mainly used in the manufacture of press parts, pipes, hoses, etc., while cast acrylic is mainly used for the manufacture of objects such as furniture, toys, plastic items, etc.

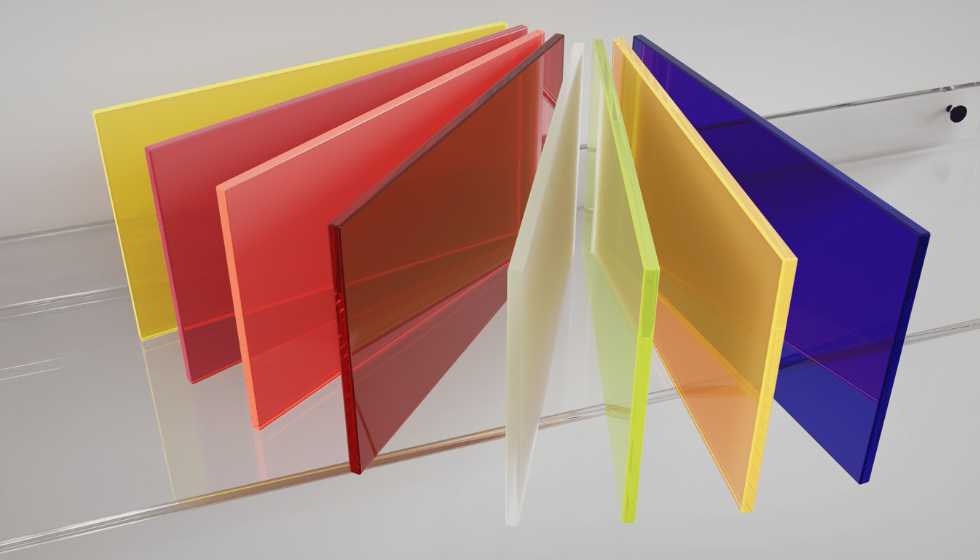

Acrylics with exclusive colors and coatings are one of the most widely used in the display industry, both for their versatility at the time of manufacture and for their optical and physical characteristics.

These materials are manufactured from a monomer, methyl acrylic, and are used in a wide variety of applications, from contact lenses and spectacle lenses to packaging materials and electronic components.

Transparent acrylics are generally colorless or light yellow, while translucent and opaque acrylics can be of a wide range of colors.

Acrylic is a very versatile material that can be used in interior decoration in a very creative way. It is a transparent material, resistant and very easy to manipulate, which makes it ideal for the realization of various decorative elements.

One of the easiest ways to use acrylic in interior decoration is by making transparent panels.

These panels can be used as room dividers or as wall, door or furniture coverings. They can also be used to create customized shelving or display cases.

Another way to use acrylic in interior decoration is by making three-dimensional objects.

It is a very moldable material, so that objects of very different shapes and sizes can be made. These objects can be used as decorative elements or as part of a scenography.

Finally, acrylic can also be used for furniture manufacturing. It is a very resistant material, making it ideal for making tables, chairs, shelves or even beds.

It can also be used to make pictures, mirrors or any other decorative element.

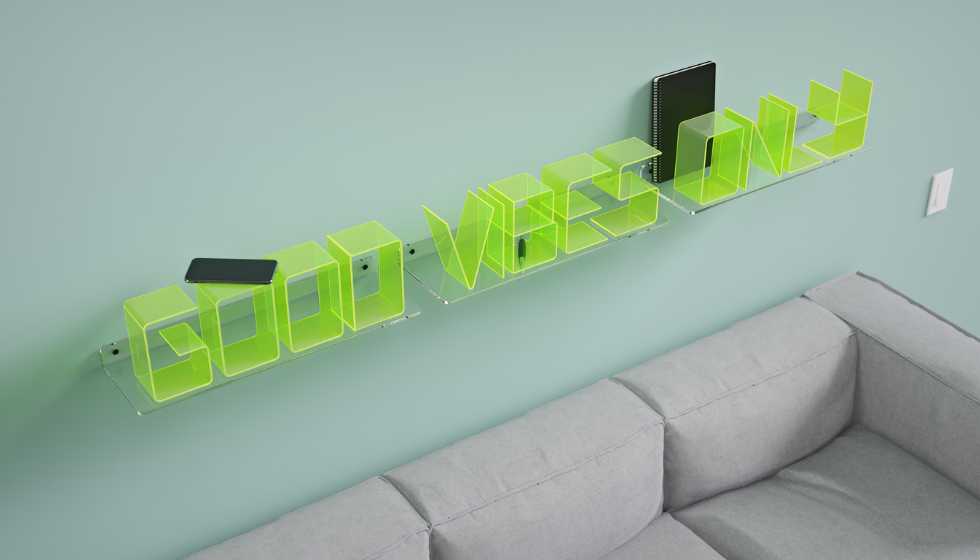

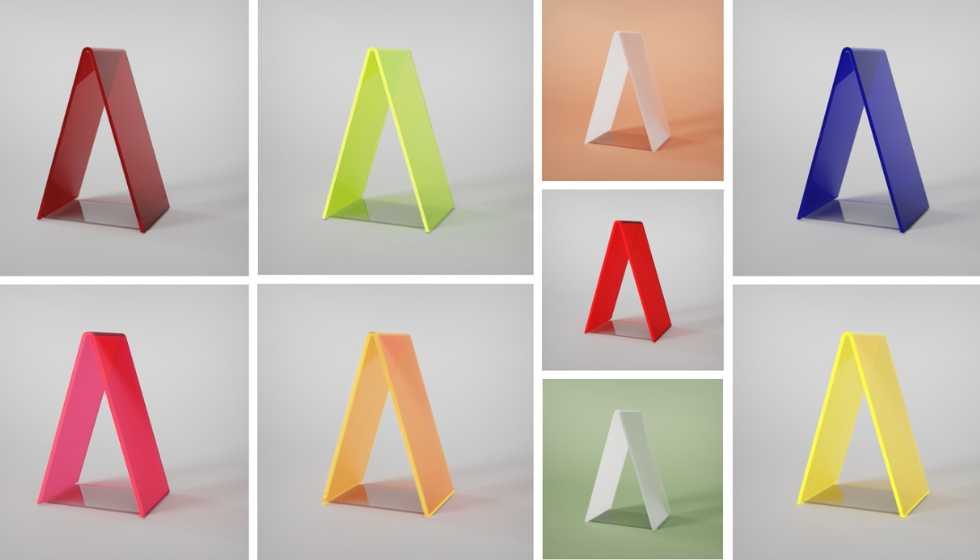

All these characteristics and peculiarities of acrylic make the Anita letters unique and so special.

It allows you to build a whole typography in three dimensions and to form the initial, word or name of your choice. And as if this were not enough, thanks to the material, it is also possible to create the letters in a wide variety of colors, achieving a spectacular effect when the light hits the colored letters.

Shopping guide

New products, News, Promotions

Subscribe and get 10% off on your first purchase.

anita letters

New products, News, Promotions

Subscribe and get 10% off on your first purchase.

New products, News, Promotions

Subscribe and get 10% off on your first purchase.

Sign up for our newsletter and

get a 10% off on your first order.

©2023 Anita Letters. All rights reserved.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

This website uses the following additional cookies:

(List the cookies that you are using on the website here.)

Please enable Strictly Necessary Cookies first so that we can save your preferences!

More information about our Cookie Policy